‘World’s First’ Subsea Power Hub for Floating Wind to Be Tested in Norway

Aker Solutions and the Marine Energy Test Centre (METCentre) in Norway have signed a front-end engineering and design (FEED) contract for a pilot project which will see Aker Solutions testing its new power transmission technology at the METCentre’s offshore test area that houses demonstration floating wind turbines.

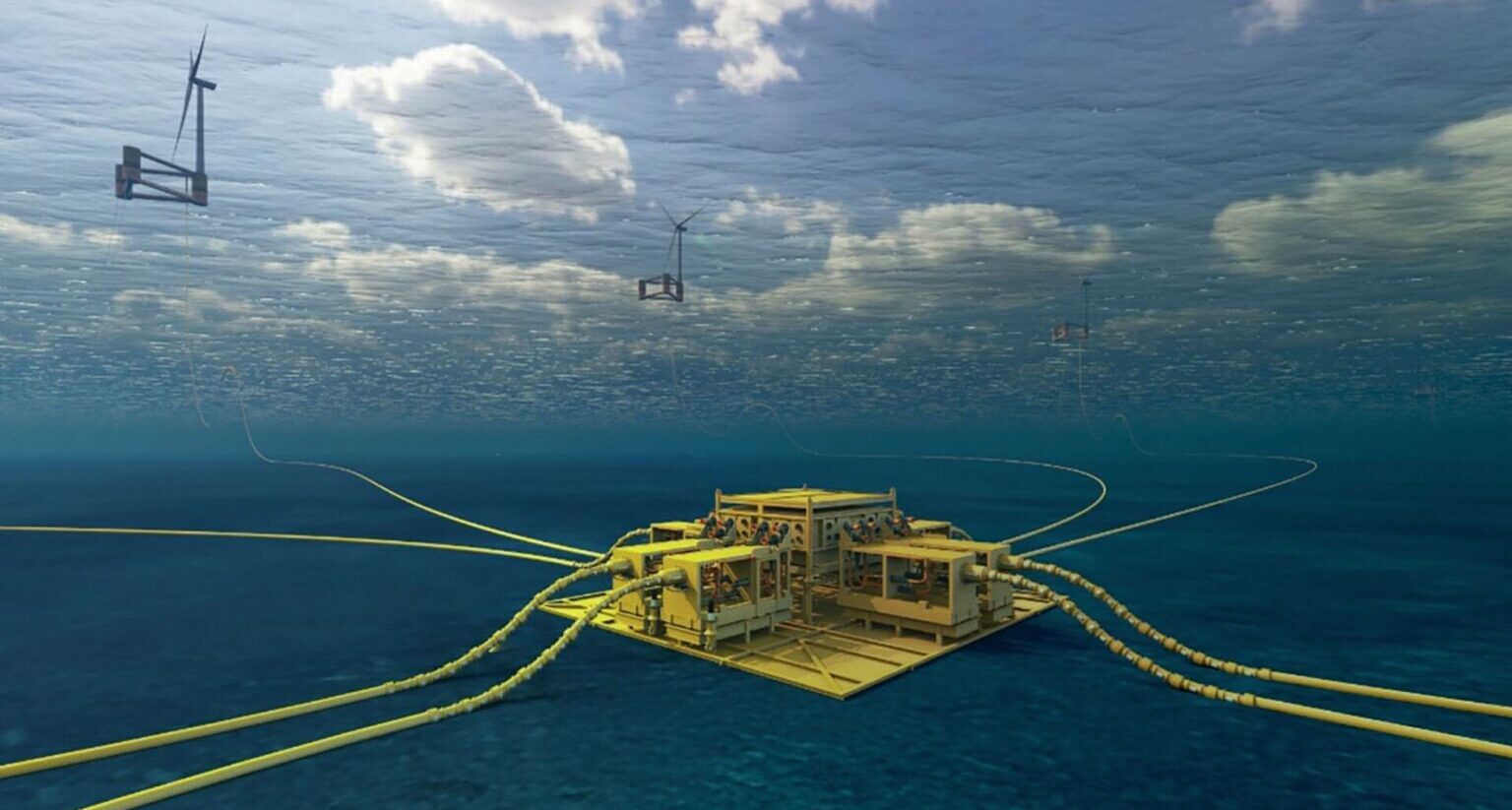

According to Aker Solutions, the new power system technology, called the Subsea Collector, connects multiple wind turbines in a star configuration instead of the traditional daisy chain pattern and has the potential to reduce the costs of offshore transmission infrastructure by up to 10 per cent.

The main components of the Subsea Collector are a 66kV wet mate connection system, subsea switchgear with supervisory control and data acquisition, and a static export cable.

“The first-of-its-kind system has been developed following the proven success of similar technologies in large installation projects and Aker Solutions’ experience in subsea power solutions for subsea gas compression and more recently for floating offshore wind like Equinor’s Hywind Tampen,” Aker Solutions said in a press release on 3 January.

Aker Solutions says that the system’s design allows for more flexibility in offshore wind farm architecture and construction, as well as for reduced cable length per turbine and wind farm, and less vessel time and installation costs.

Initial findings support total cost savings on a 1 GW floating wind farm of up to 10 per cent, according to the company.

For the pilot project in Norway, Benestad will supply the wet mate connection system and ABB will deliver subsea switchgear. The Subsea Collector at the METCentre will be installed by Windstaller Alliance, an alliance between Aker Solutions, DeepOcean and Solstad Offshore, with Aker Solutions also providing the static export cable to shore.

“The Subsea Collector is a great example of true industry collaboration. Combining Aker Solutions’ vast subsea experience with our partner’s proven control and connection systems, we aim to solve challenges currently facing the offshore wind sector. We hope this project will result in a field proven system that can benefit the industry for many years to come,” said Jo Kjetil Krabbe, executive vice president of Power Solutions at Aker Solutions.

METCentre’s offshore wind test area, located 10 kilometres off the southwestern coast of Karmøy in Norway, currently has two floating wind turbines and will expand to seven floating wind turbines from 2026.

For its new cable infrastructure, the METCentre evaluated several configurations and decided to move forward with a pilot installation of Aker Solutions’ Subsea Collector to enable the expansion of the test site, according to the press release from Aker Solutions.

“This pioneering project will contribute to shaping the infrastructure in future large scale floating wind parks. The technology is under development, and the project demonstrates how Norwegian subsea expertise from the oil and gas industry drives innovation forward within floating offshore wind on a global scale,” said Arvid Nesse, CEO of METCentre and Norwegian Offshore Wind.

Source offshore wind