“Three in and One out” for Submarine Cables

Recently, Aker Solutions, an offshore giant, launched a submarine cable connection device that can greatly reduce the costs related to collector circuits in offshore wind projects.

In early European offshore wind projects, the on-site collector circuits were generally arranged in a ring because low system reliability and high electricity price could result in huge losses if any cable fails. With the ring-shape collector circuits, when one submarine cable failed, the power could be sent in the other direction.

Later, as offshore wind paid more attention to cost control, on-site collector circuits began to adopt a chain layout, where the cross-section of the submarine cable gradually increases as the transmission capacity increases.

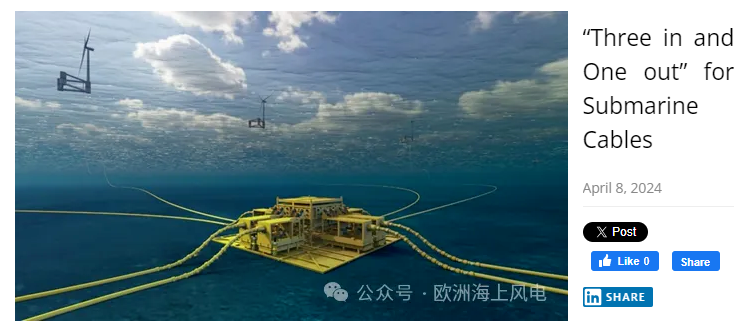

The submarine cable connection device launched this time is called “Subsea Collector”. It is essentially a submarine cable branch box that can collect the transmission capacity of three submarine cables and centrally access the next wind turbine or booster station. The wet plugging device was provided by Benestad and the switchgear was provided by ABB.

The advantages of using this device are:

- Smaller cross-section of some submarine cables;

- Fewer “detours” for the submarine cable with the right location of the connecting device;

- For the wind turbine connected to it, the number of connected submarine cables is reduced from 2 to 1, which lowers the difficulty of construction and eliminates the need for a ring main unit inside the wind turbine.

Aker Solutions has signed an agreement with The Marin Energy Test Centre (METCentre) to test the connection device in the latter’s offshore trial area.

Source: EuropeanWind